In the first seven months of the current calendar year (March-Oct 2020), over 4.755 million barrels of gas condensate was produced at phase 1 of the South Pars Gas Field, a supervisor at the first refinery of South Pars Gas Complex said.

“Almost 40,000 barrels of gas condensate is sent to storage tanks daily for export ,” ISNA quoted Behrouz Heydari as saying.

The refinery also produced more than 5 billion cubic meters of sweet gas in the seven months, he added.

“Incoming sour gas to the refinery is first separated from the gas condensate and then refined in two units,” Heydari noted.

Almost 25 million cubic meters of gas is refined a day and enters the national gas grid through a 56-inch pipeline.

Moreover, the hydrogen sulfide (H2S) that is separated in the sweetening unit is directed to the sulfur recovery units and 200 tons of sulfur are produced in granulated form on a daily basis, Heydari added.

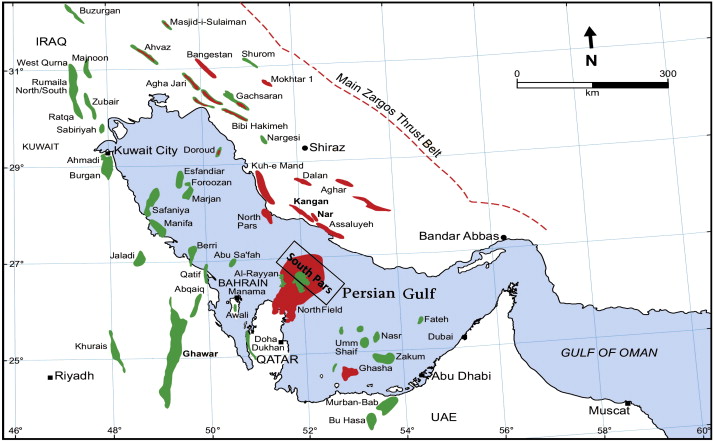

South Pars is the world's largest gas field shared between Iran and Qatar. It is developed in 24 phases of which 23 are operating.

The field is estimated to contain large deposits of natural gas, accounting for about 8% of the world’s reserves, and approximately 18 billion barrels of condensates.

South Pars Gas Complex accounts for 75% and 92% of total natural gas and gas condensate output, respectively.

SPGC produces 685,000 barrels of gas condensates per day, a major part (500,000 barrels) of which is delivered to the Persian Gulf Star Refinery in Hormozgan Province to be converted into gasoline.

Gas condensate is also sold to petrochemical plants in Asalouyeh and Mahshahr in the south as feedstock to produce value-added products.

Gas condensate production is getting a boost as Iran increases gas output (850 million cubic meters per day, and expects to boost it to 1 billion cubic meters by March).